High Early Strength Concrete Additive Polycarboxylate Ether Superplasticizer/PCE Liquid

High Early Strength Concrete Additive Polycarboxylate Ether Superplasticizer/PCE Liquid 1.Introduction Polycarboxylate s

Basic Info

| Model NO. | ELt |

| Type | water-reducing admixture |

| Solid Content(%) ≥ | Solid 40 or 50 |

| Density(g/cm3) | 1.05 |

| Chloride Content (% | <=0.02 |

| pH Value | 8.0 |

| Product Name | Concrete Cement Polycarboxylate Superplasticizer |

| Cement Paste Fluidity (mm) | >=240 |

| Water Reduction (%) | >=25 |

| Corrosion to Steel Bars | None |

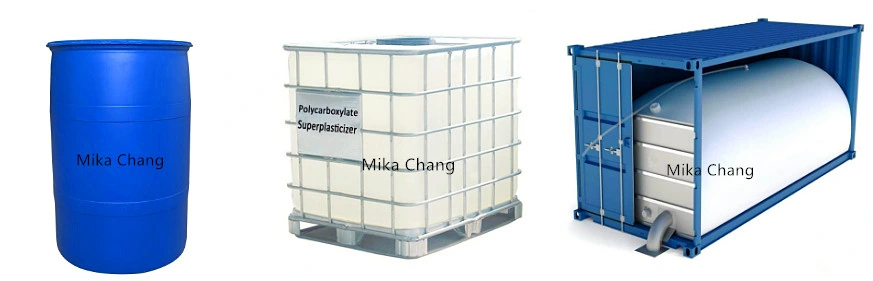

| Transport Package | 230kg/200L PE Drum, 1100kg/IBC Tank, |

| Specification | ISO |

| Trademark | elite-indus |

| Origin | China |

| HS Code | 3824401000 |

| Production Capacity | 800000ton Per Year |

Product Description

High Early Strength Concrete Additive Polycarboxylate Ether Superplasticizer/PCE Liquid1.Introduction

Polycarboxylate superplasticizer is a polycarboxylate based high range water-reducing admixture which enables concrete to be produced

with very low water to cement ratios.Polycarboxylate superplasticizer does not contain added chlorides and will not promote corrosion in steel.

Polycarboxylate superplasticizer is compatible with air-entraining agents, microsilica, accelerators and many other admixtures; however,

each material should be added to the concrete separately.Polycarboxylate superplasticizer complies with the requirements of the following

standards: ASTM C 494, Type A & F. BS EN 934-2.

Polycarboxylate superplasticizer It can improve the flowability of concrete while significantly reduce the mixing water of concrete. It has high

water-reducing rate(40%) to meet the performance requirements of self-compacting concrete, high-performance concrete and precast.

And it also has the function on early strength.

ELT-WR High Range Water Reducing ELT-SRB LOW Slump Retention ELT-SRA High Slump Retention

2.Technical specification

| Item Description | Specification | |

| Elt-WR (Water reducing style) | Elt-SR (Slump retention style) | |

| Solid Content(%) ≥ | 40±1.0 or 50±1.0 | 40±1.0 or 50±1.0 |

| Appearance | Brown /Colorless/Yellowish Liquid | Brown /Colorless/Yellowish Liquid |

| Density(g/cm3) | 1.05 | 1.05 |

| Chloride Content (% )≤ | 0.02 | 0.02 |

| PH Value | 6.5±1.0 | 6.5±1.0 |

| Cement paste Fluidity (mm) ≥ | 230 | 220 |

| Water Reduction (%)≥ | 25-36 | 25-33 |

| Air Content (%)≤ | 3.0 | 3.0 |

| Corrosion to Steel Bars | None | None |

3, Performance

1), high water reduction, water reduction rate of more than 25 to 40 percent.

2), high flow, high slump, concrete slump when small losses.

3), there is a significant hardening of concrete reinforcing effect, 3d strength can be increased 50 ~100%, 7d, 28d strength can be increased by

30-50%, the late strength remained stable growth.

4), good workability of fresh concrete, no segregation,good pumpability, sclerosing outside light in solid concrete.

5), chlorine-free, low-alkali, no corrosion of steel.

6), gas content can be adjusted according to project needs.

7), significantly improve the concrete antifreeze, impermeability,low-carbon capabilities, as well as anti-shrinkage and other indicators, can

significantly extend the service life of concrete.

8), the product has a good adaptability to meet the many varieties of cement, especially for fly ash, ground slag and other active admixture

preparation of high-strength, high flow, high performance concrete.

9) the product non-toxic, harmless to health and the environment are safe.

4.Application

1, for the preparation of various levels of pumping concrete,long-distance transport of commercial concrete.

2, suitable for high-strength concrete, fluidized concrete,self-compacting, mass concrete, high performance concrete,concrete structure of water.

3, for a variety of civil works, high-rise reinforced concrete frame structure, Especially for highway, railway, bridge engineering, tunnel engineering,

hydraulic dams, nuclear power engineering, ports, docks,and other underground facilities that require high durability of concrete large concrete

structure, but also for large prestressed concrete beams, plates production , steam curing concrete and so on.

5.Package & Storage

1. Liquid product: 230kg/200L PE drum ,1100kg/IBC tank,.

2. Sealed stored under 0-35ºC,far away from sunlight.

3. Shelflife is normally 12 month. It is tested eligibility and then used when it exceeds.

6.Handling Notes

1. Elt-WR is free from alkaline. It is no toxic, hazardous, and corrosive. It is inedible.

2. When it contacts to eyes and skin, the affected area shall be immediately rinsed with plenty of water for minutes. Consult a physician

if irritation persists.

3. Keep container closed when it is not in use. Do not store the product directly under sunlight.

7,our company:

Anhui Elite Industrial Co.,LTD was established in 2007, has become one of the leading and professional suppliers of all kinds of

Concrete additive in the world market.

Our Product were widely used in all kinds of concrete,mortar,plaster projects and exported to more than 30 countries, Such as USA,

Russia, Germany, Australia, Chile, UAE, Korea, Vietnam, Africa etc.

Our Product was made by 100% Virgin Material with advanced equipment , we have one full set of precise testing instrument,

testing equipment and quality inspection team, technology research and development team. the management system was certified

by ISO9001 and our products have been passed the CE Certification.

Our Mainly Product and Production Capacity as below:

| Item | Capacity/Annual |

| Polypropylene Fiber (PP Fiber) | 15000mts |

| Polyester Fiber(PET Fiber) | 6000mts |

| Polyvinyl Alcohol Fiber( PVA Fiber) | 30000mts |

| Polyacrylonitrile Fiber(PAN Fiber) | 6000mts |

| Naphthalene Formaldehyde Sulphonate | 300000mts |

| Polycarboxylate Superplasticizer | 150000mts |

PCE Powder SM Superplasticizer SNF Powder

Micro Synthetic Fiber ELT-Mono Micro Synthetic Fiber ELT-Fibril Macro Synthetic Fiber ELT-Embossed

Macro Synthetic Fiber ELT-Twist Macro Synthetic Fiber ELT-Wave Hook End Steel Fiber ELT-HE

8,Our Certificate:

Send to us